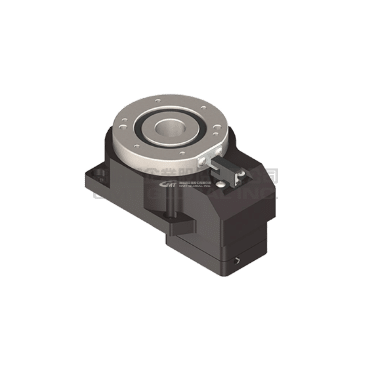

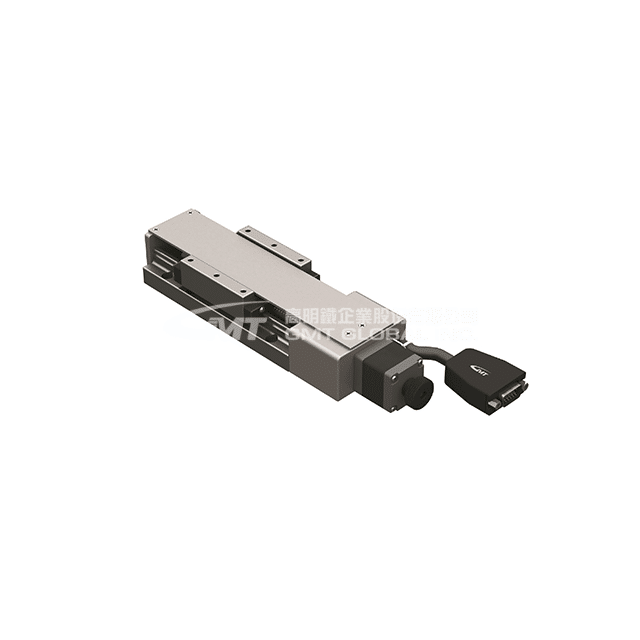

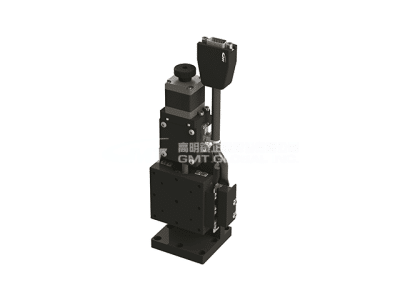

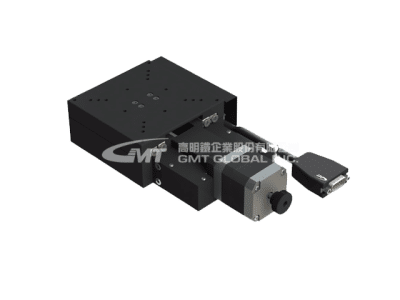

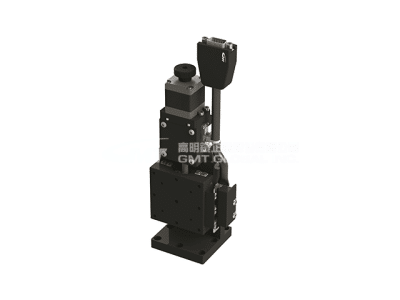

CXC80 – Standard

★ Guide- Circular linear ball guiding, Gothic arc-groove formed by dual arc-grooves individually on upper and lower rails of body. Ball moving in single groove is structured by 2 points-contact, and total 4contact points in dual arc-groove to form strong rail constructure.

★ Transmission Parts-Ball screw, It transmits through the ball involving in the locknut and screw to reach the accuracy and longer operation lifetime.

★ Material-Stainless Steel, Carbon Steel

★This product pic. shows as CXC60100-S2NN-ND which is only for reference, please base on below specification for further information.

|

Model No. |

CXC8030-S2NN-ND-P1 CXC8030-F2NN-ND-P1 |

CXC8030-S2NN-ND-P2 CXC8030-F2NN-ND-P2 |

CXC8050-S2NN-ND-P1 CXC8050-F2NN-ND-P1 |

CXC8050-S2NN-ND-P2 CXC8050-F2NN-ND-P2 |

CXC8075-S2NN-ND-P1 CXC8075-F2NN-ND-P1 |

CXC8075-S2NN-ND-P2 CXC8075-F2NN-ND-P2 |

||

|

Mechanical Spec. |

Table Size (mm) |

80 X 80 | ||||||

|

Travel Stroke (mm) |

30 | 50 | 75 | |||||

|

Drive Type |

Ball screw Ø8

lead 1 mm |

Ball screw Ø8

lead 2 mm |

Ball screw Ø8

lead 1 mm |

Ball screw Ø8

lead 2 mm |

Ball screw Ø8

lead 1 mm |

Ball screw Ø8

lead 2 mm |

||

|

Rail |

Circular Linear Ball Guiding | |||||||

|

Stage Material / Surface Treatment |

S:Stainless Steel / Nickel Plating

F:Carbon Steel / Nickel Plating |

|||||||

|

Main Unit Weight (Kg) |

1.79 | 1.86 | 2.03 | |||||

|

Coupling |

FAMCS11.6-5*5 | |||||||

|

Accuracy Level |

N:Standard grade | |||||||

|

Wiring Method |

N:GMT Standard | |||||||

|

Precision Spec. |

Resolution (Pulse) (µm) |

5 (Full)

2.5 (Half) |

10 (Full)

5 (Half) |

5 (Full)

2.5 (Half) |

10 (Full)

5 (Half) |

5 (Full)

2.5 (Half) |

10 (Full)

5 (Half) |

|

|

Max. Speed (Full Step) (mm / sec) |

20 | 40 | 20 | 40 | 20 | 40 | ||

|

Positioning Presion (µm) |

15 | |||||||

|

Repeatability Precision (µm) |

± 1 | |||||||

|

Load Capacity (Kgf) |

16 | |||||||

|

Missed Step (µm) |

3 | |||||||

|

Parallelism (µm) |

20 | |||||||

|

Dynamic Straightness (µm) |

3 | |||||||

|

Dynamic Parallelism (µm) |

10 | |||||||

|

Electrical Spec. |

Motor |

Type / Shaft Numbers |

2-phase stepper / ☐ 28 double shafts | |||||

|

Brand / Model |

GMT / 2MS-N28D32A | |||||||

|

Driver Brand / Model |

GMT / GTR22G-D (Additional options) | |||||||

|

Connector |

Stage Side Connector |

15-Pin male end connetor D-SUB / 12-Pin male end connetor HRS | ||||||

|

Controller Side Connector |

15-Pin female end connetor D-SUB / 12-Pin female end connetor HRS (Additional options) | |||||||

|

Sensor |

Origin Sensor |

Photoelectric sensor GMT-sensor | ||||||

|

Limit Sensor |

||||||||

|

Origin Approximation Sensor |

N / A | |||||||

|

Power Voltage |

24V ± 10% | |||||||

|

Control Output |

NPN open collector output under 24V 8mA | |||||||

|

Output Control |

Testing (sensing):output transistor OFF (closed) | |||||||

|

Model No. |

CXC80100-S2NN-ND-P1 CXC80100-F2NN-ND-P1 |

CXC80100-S2NN-ND-P2 CXC80100-F2NN-ND-P2 |

CXC80150-S2NN-ND-P2 CXC80150-F2NN-ND-P2 |

CXC80200-S2NN-ND-P2 CXC80200-F2NN-ND-P2 |

CXC80250-S2NN-ND-P2 CXC80250-F2NN-ND-P2 |

CXC80300-S2NN-ND-P2 CXC80300-F2NN-ND-P2 |

||

|

Mechanical Spec. |

Table Size (mm) |

80 X 80 | ||||||

|

Travel Stroke (mm) |

100 | 150 | 200 | 250 | 300 | |||

|

Drive Type |

Ball screw Ø8

lead 1 mm |

Ball screw Ø8

lead 2 mm |

||||||

|

Rail |

Circular Linear Ball Guiding | |||||||

|

Stage Material / Surface Treatment |

S:Stainless Steel / Nickel Plating

F:Carbon Steel / Nickel Plating |

|||||||

|

Main Unit Weight (Kg) |

2.2 | 2.5 | 2.78 | 3.08 | 3.38 | |||

|

Coupling |

FAMCS11.6-5*5 | |||||||

|

Accuracy Level |

N:Standard grade | |||||||

|

Wiring Method |

N:GMT Standard | |||||||

|

Precision Spec. |

Resolution (Pulse) (µm) |

5 (Full)

2.5 (Half) |

10 (Full)

5 (Half) |

|||||

|

Max. Speed (Full Step) (mm / sec) |

20 | 40 | ||||||

|

Positioning Presion (µm) |

15 | 20 | 30 | |||||

|

Repeatability Precision (µm) |

± 1 | |||||||

|

Load Capacity (Kgf) |

16 | |||||||

|

Missed Step (µm) |

3 | |||||||

|

Parallelism (µm) |

20 | |||||||

|

Dynamic Straightness (µm) |

3 | 5 | 8 | |||||

|

Dynamic Parallelism (µm) |

10 | 15 | 20 | 30 | ||||

|

Electrical Spec. |

Motor |

Type / Shaft Numbers |

2-phase stepper / ☐ 28 double shafts | |||||

|

Brand / Model |

GMT / 2MS-N28D45A | |||||||

|

Driver Brand / Model |

GMT / GTR22G-D (Additional options) | |||||||

|

Connector |

Stage Side Connector |

15-Pin male end connetor D-SUB / 12-Pin male end connetor HRS | ||||||

|

Controller Side Connector |

15-Pin female end connetor D-SUB / 12-Pin female end connetor HRS (Additional options) | |||||||

|

Sensor |

Origin Sensor |

Photoelectric sensor GMT-sensor | ||||||

|

Limit Sensor |

||||||||

|

Origin Approximation Sensor |

N / A | |||||||

|

Power Voltage |

24V ± 10% | |||||||

|

Control Output |

NPN open collector output under 24V 8mA | |||||||

|

Output Control |

Testing (sensing):output transistor OFF (closed) | |||||||

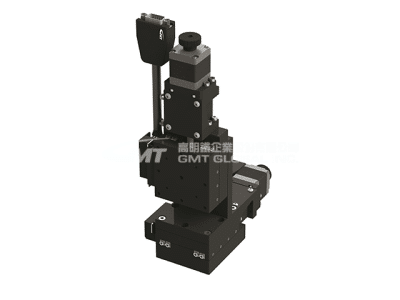

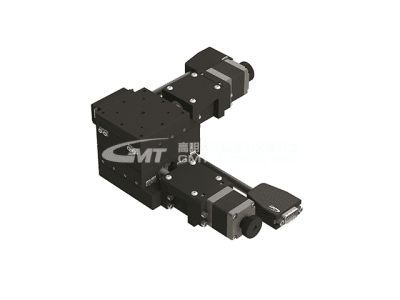

| System Configuration Diagram |

| ♦ For selection of the drivers preferred, please refer to the reference table or the catalogue of Motor・Driver.

♦ All of the drivers chosed are the specification of GMT preferred. For different needs, please choose the suitable drivers according to real functional needs. |

| Axis Definition |

| GMT has defined different axis as the following figuration according to the movement direction:

Horizontal movement direction is X and Y axis. Vertical movement direction is Z axis. Movement around X, Y, Z axis is defined to α axis, β axis, and θ axis. Green arrows present the specified axis movement direction. |

Motor・driver Reference Table |

|

|

|

Reviews

There are no reviews yet.