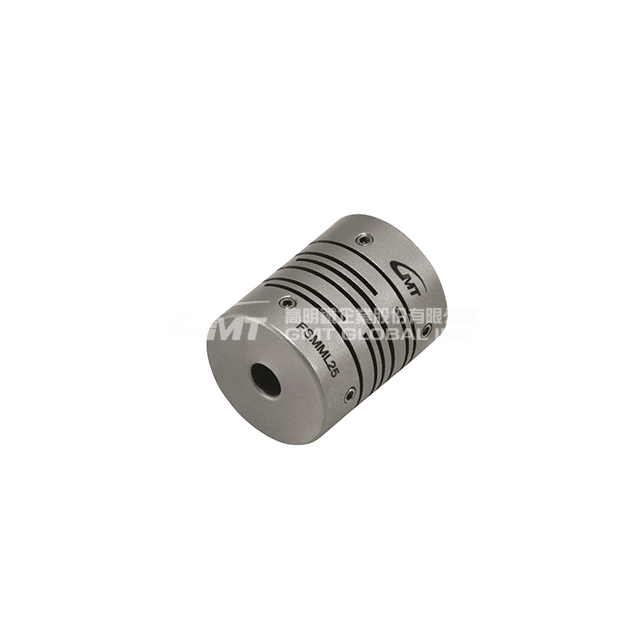

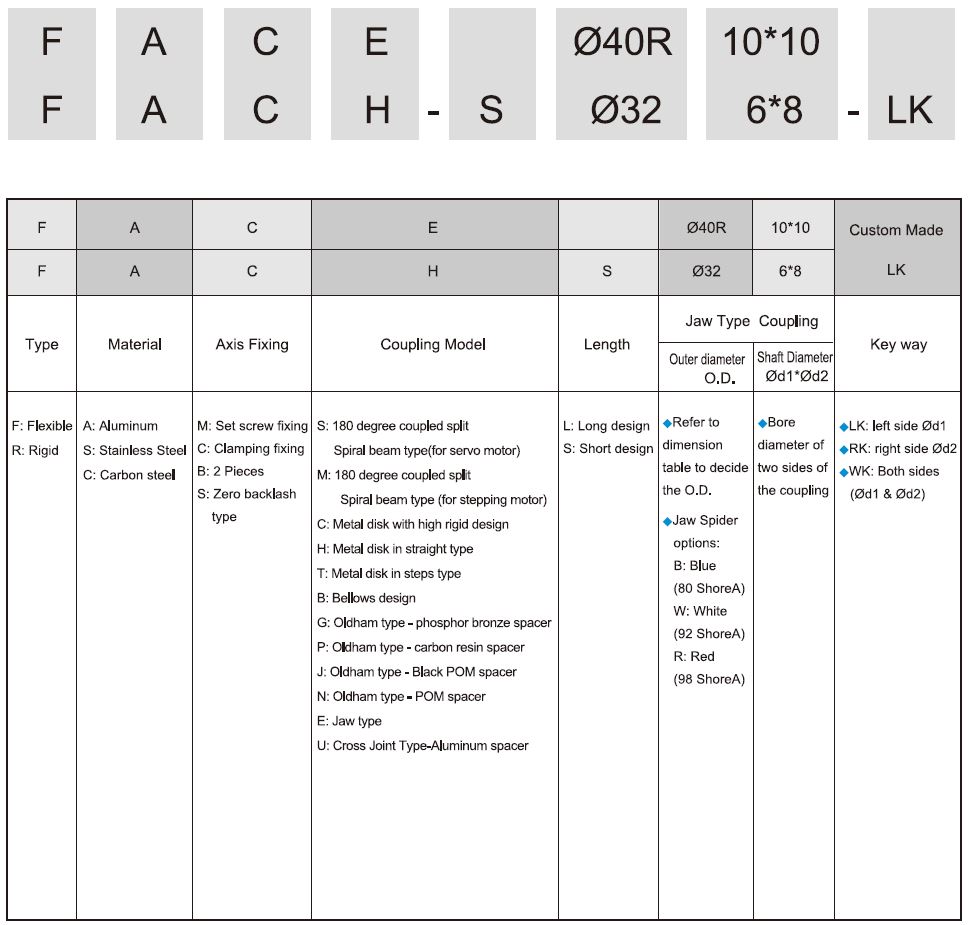

FSMML25

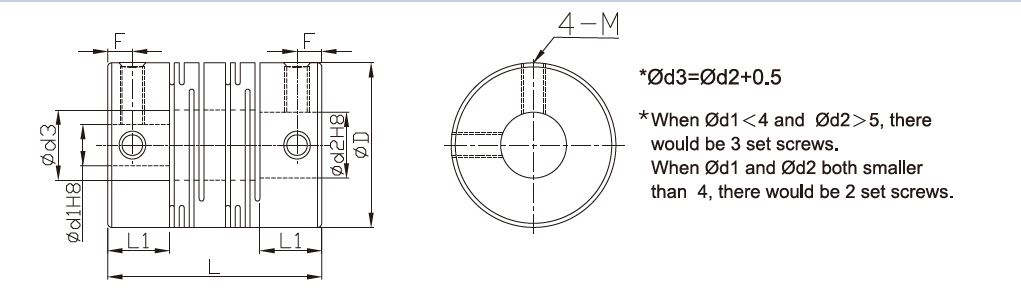

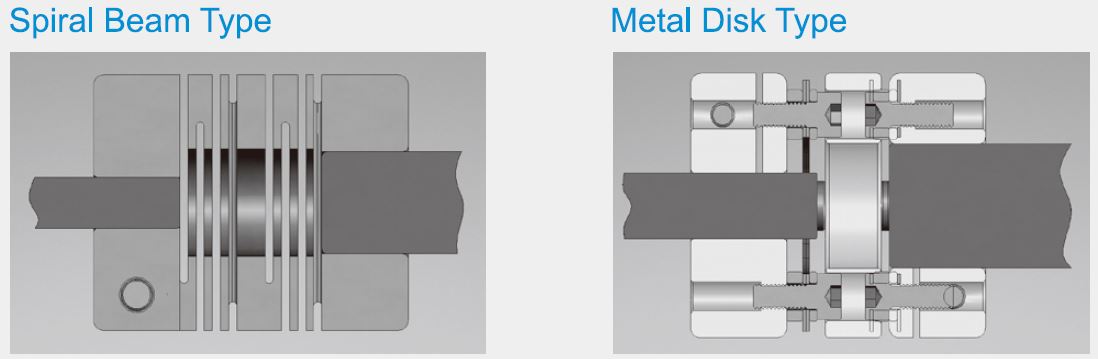

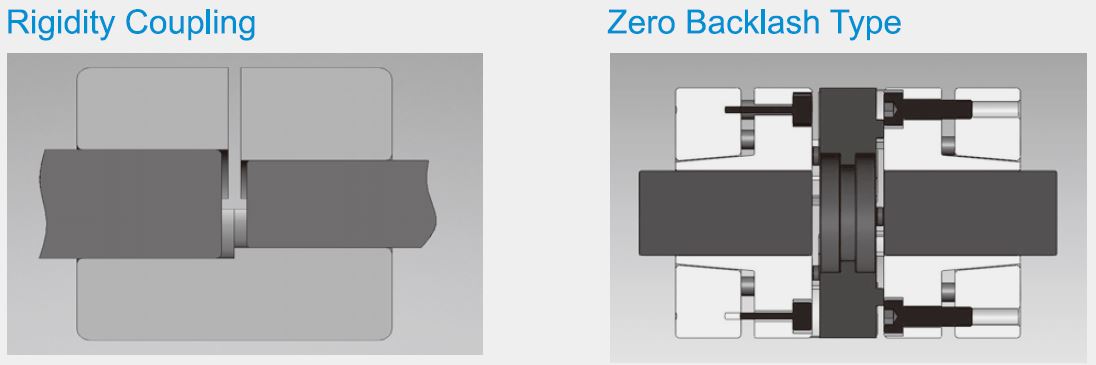

★ Flexible coupling – Spiral beam type – Set screw fixing – Long type.

★ Zero rotation backlash.

★ The flexure allowed by the beam portion of the coupling is capable of accommodating angular, parallel, and axial misalignment.

★ High wrench torque rigidity and sensitivity.

★ Rotation character of clockwise or anti-clockwise is exactly the same.

★ Free maintenance, oil-resist and anti-corrosiveness.

★ Offset of angular, parallel, or axial deviation are individual allowed value, so couple reasons of axial offset appearing at same time would reduce the unit allowable value.

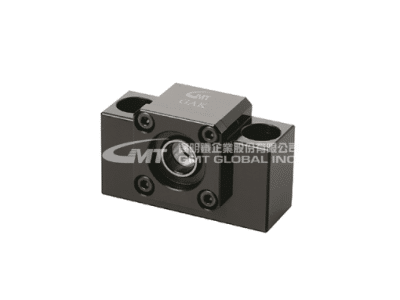

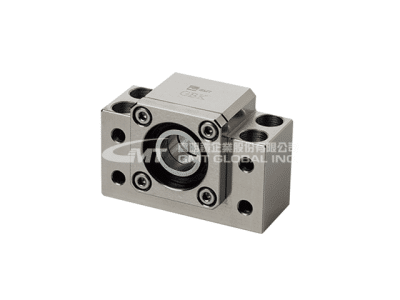

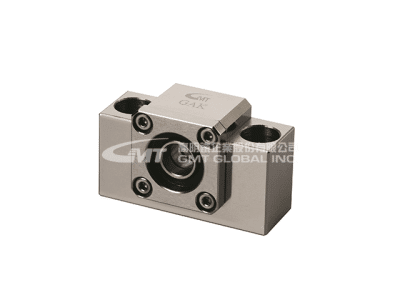

★ The product picture is FSMML25 for reference, please base on below specification for further information.

Reviews

There are no reviews yet.