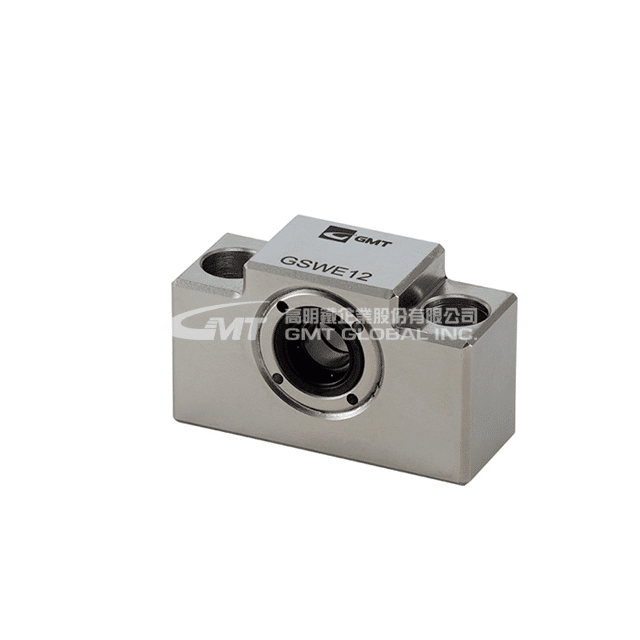

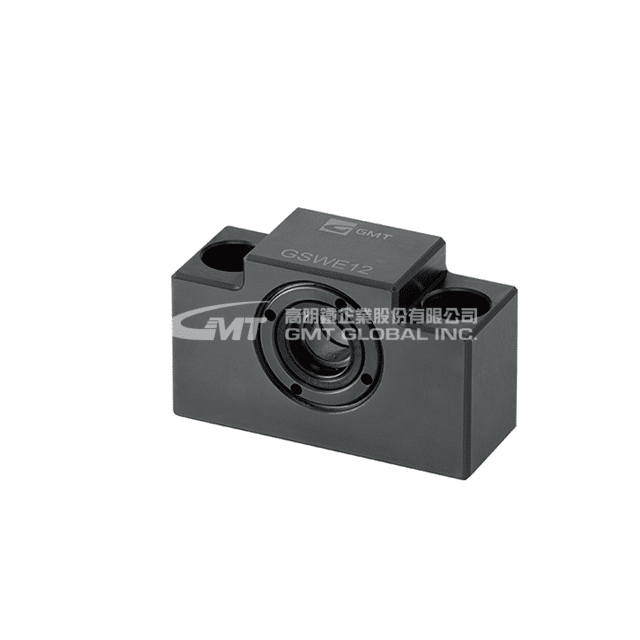

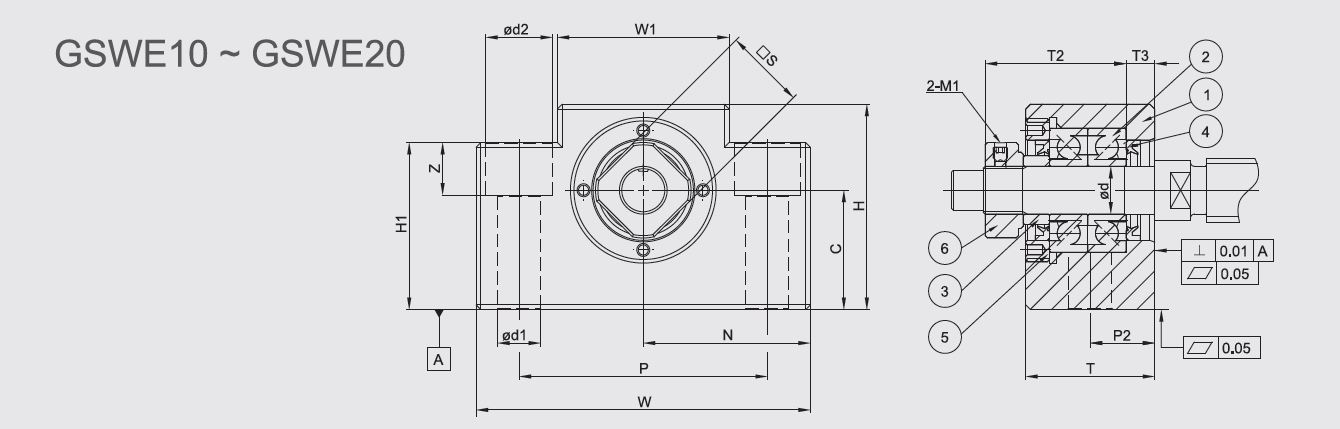

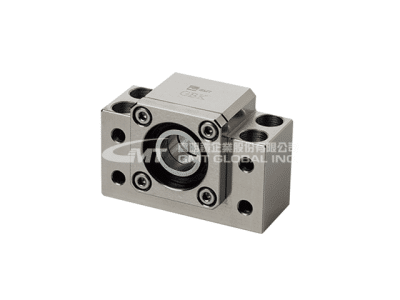

GSWE10-S Standard

★ Support Unit – Standard – Rectangle fixed side.

★ Applied angular contact bearings.

★ Pre-loaded grade is provided Light, Medium and heavy.

|

Model No. |

GSWE10-SL |

GSWE10-SM |

GSWE10-SH |

||

|

Specification |

Material |

S50C | |||

|

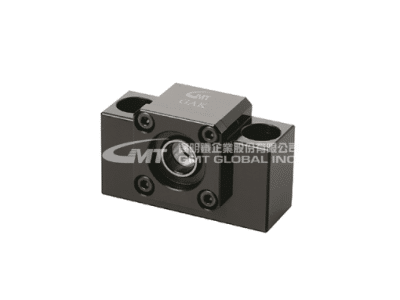

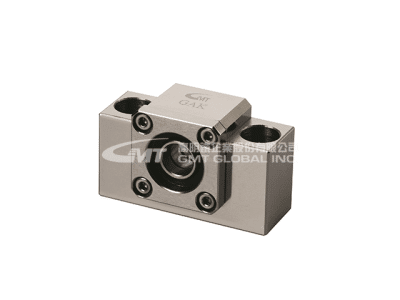

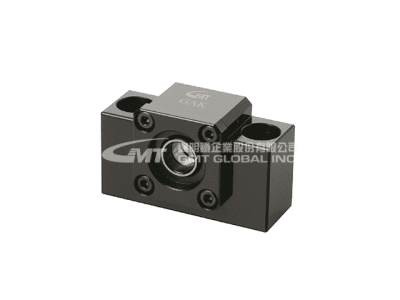

Surface Finish |

B:Black Dyed

N:Ni-Plating |

||||

|

Pre-loaded |

L:Light | M:Medium | H:Heavy | ||

|

Dimensions |

Ød (mm) |

10 | |||

|

T (mm) |

27 | ||||

|

T1 (mm) |

8.5 | ||||

|

T2 (mm) |

29.5 | ||||

|

T3 (mm) |

6 | ||||

|

W (mm) |

70 | ||||

|

W1 (mm) |

36 | ||||

|

H (mm) |

43 | ||||

|

H1 (mm) |

35 | ||||

|

N ±0.02 (mm) |

35 | ||||

|

C (+0, -0.02) (mm) |

25 | ||||

|

P (mm) |

52 | ||||

|

P2 (mm) |

– | ||||

|

P3 (mm) |

– | ||||

|

Ød1 (mm) |

9 | ||||

|

Ød2 (mm) |

14 | ||||

|

Z (mm) |

11 | ||||

|

口S (mm) |

16 | ||||

|

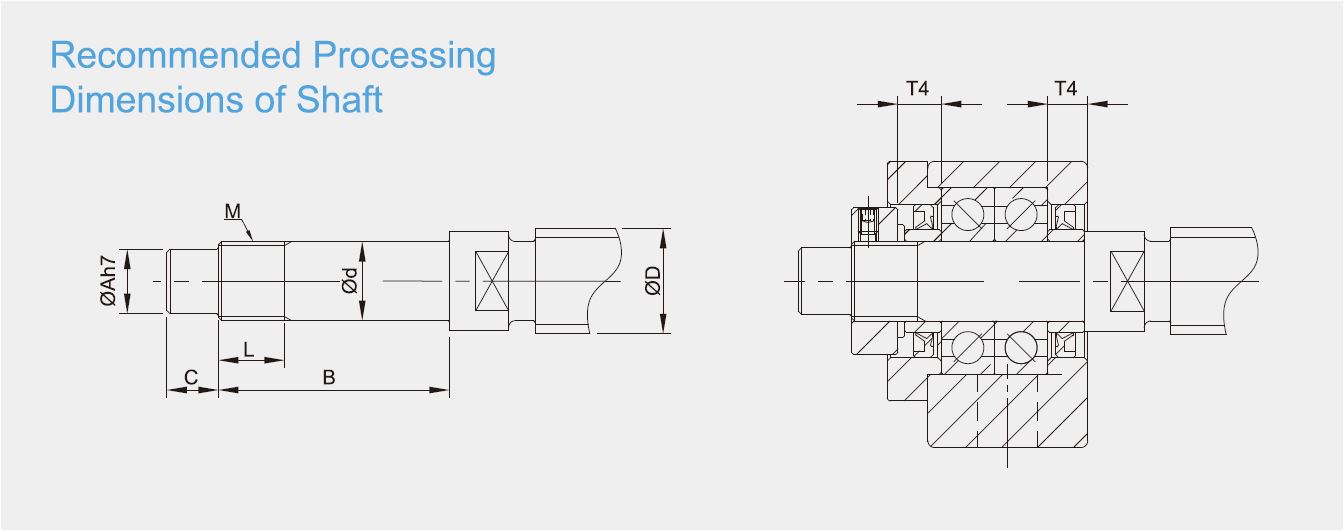

Recommended Processing Dimensions of Shaft |

Ball Screw Shaft |

ØD (mm) |

12 / 14 / 15 | ||

|

Shaft End Dia. |

Ød (mm) |

10 (-0.005, -0.012) | |||

|

Processing sizes of shaft |

ØA (mm) |

8 | |||

|

B (mm) |

36 | ||||

|

C (mm) |

15 | ||||

|

Nominal Thread |

M (mm) |

M10 x P 1.0 | |||

|

L (mm) |

11 | ||||

|

Space Ring Length |

T4 (mm) |

5.5 | |||

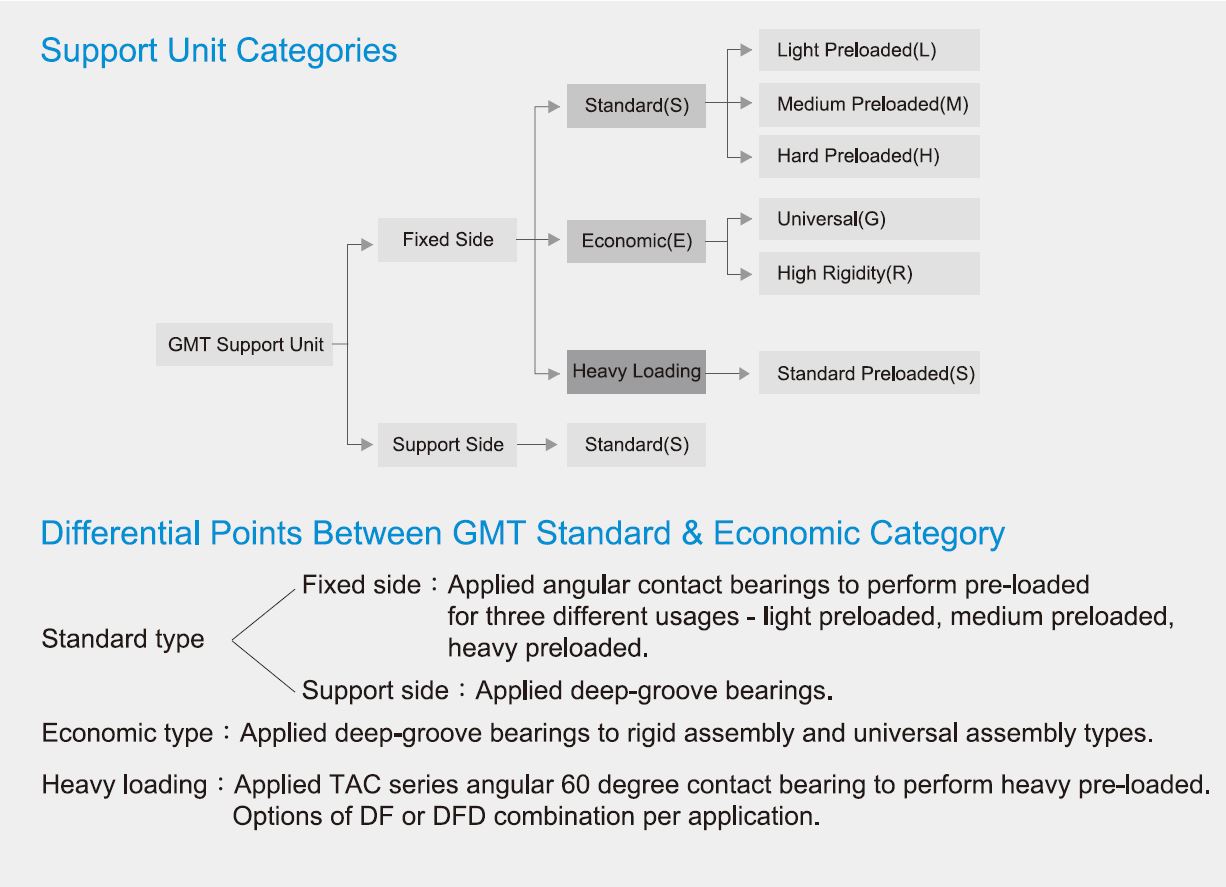

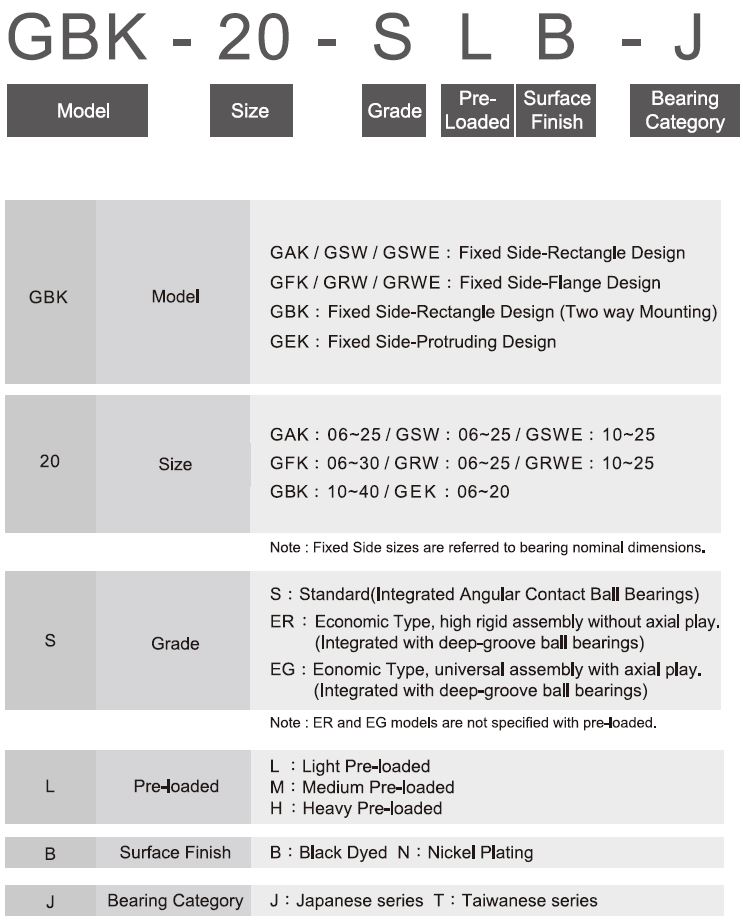

| Support Unit Introduction |

♦ Preload selection and applications – Light (L) * Machine Requirements:Equipments with small vibration and small thrust, load in one fixed direction. High accuracy is not required. Reduction of frictional force. * Application Examples:Laser welder, small CNCmill machine, cutter, welder, automatic tool changer, packing machine, material supply equipment. – Medium (M) * Machine Requirements:Equipments with load on a post. Equipments with a torque acting on it. Equipments working in one direction. Equipments with low load. Equipments with high accuracy. * Application Examples:Automated feeder, linear feeder, automatedpainting machine, precision slide table, Z-axis control on machines, PC board punch machine. Industrial robot, EDM machine, NC lathe. – Heavy (H) * Machine Requirements:High rigidity, high vibration, high thrust equipments. High load, high torque equipments. * Application Examples:Machining center spindle, NC lathe, Z-axis spindle of the machinery, milling machine, grinding wheel feeding of grinding machine.

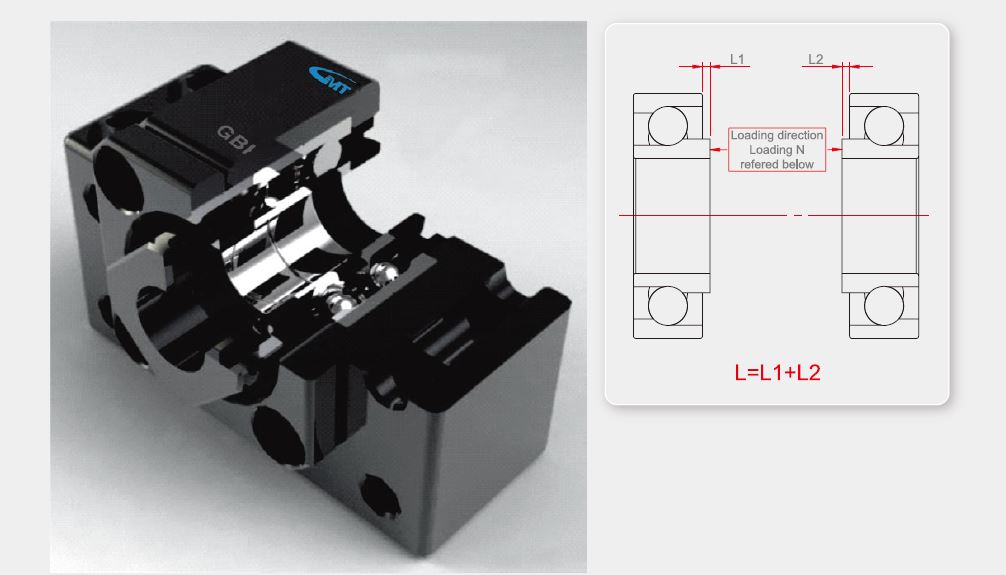

♦ Pre-Loaded Description – Purpose:1. Increase the rotational accuracy of axle 2. Increase the rigidity of axle 3. Reduce unwanted clearance 4. Reduce vibration and noise while bearing stops. – What is bearing preload?:The preload describes the process wherein a permenant thrust road is applied to the bearing, so that the bearing is secure in the groove and has no axial clearence. Apply normal force (N). Measure value of L of a pair of bearings. L=L1+L2. Press these pair of bearings on the covers to apply preload and bring these bearings together

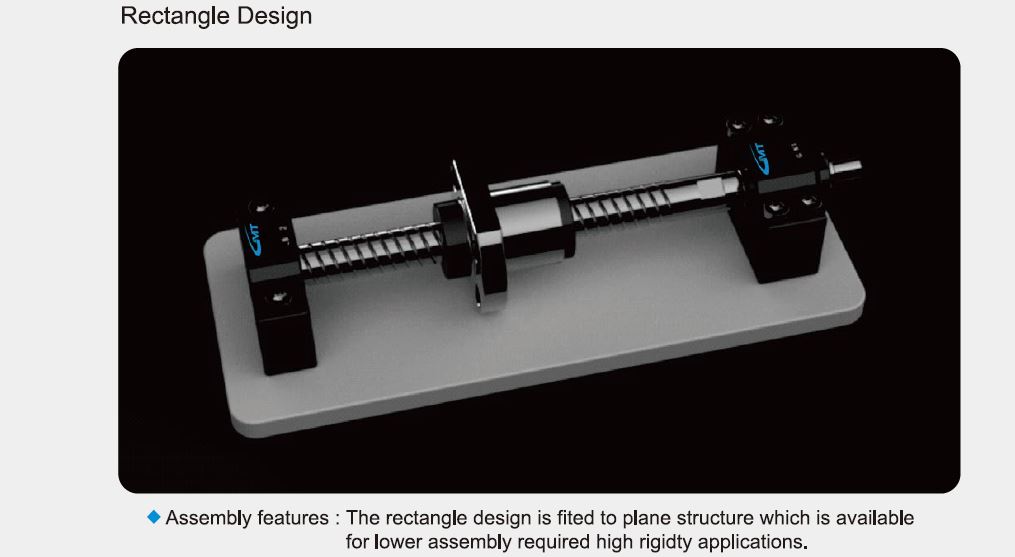

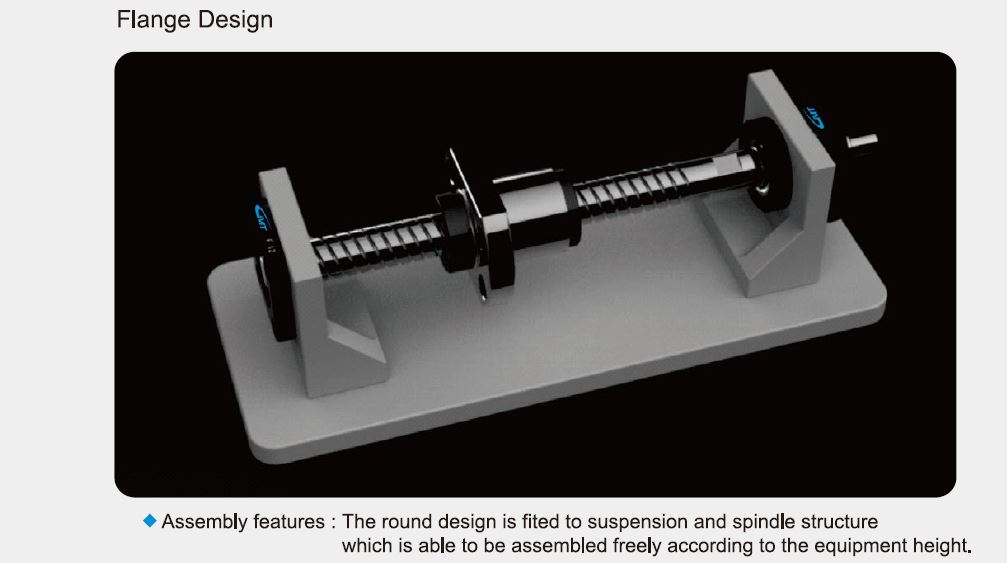

♦ Selection Notes – [ Model ]:Pick up the model according to assembly method. Assembly: 1. Plane mounting:GAK、GBK、GEK、GAF、GBF、GEF、GSW、GSWE、GUN、GTN。 2. Suspension and spindle mount:GFK、GFF、GRW、GRWE、GUR、GTR。 – [ Size ]:Decide the size according to the ballscrew shaft O.D., and the center height. – [ Grade ]:Standard and economic types for options. – [ Pre-loaded ]:Decide pre-loaded of the bearing per needs. – [ Surface Finish ]: Black dyed – Regular environment use, low humidity. Nickel plating – Clean room use. – [ Bearing category ]:Available Japanese series and Taiwanese series. |

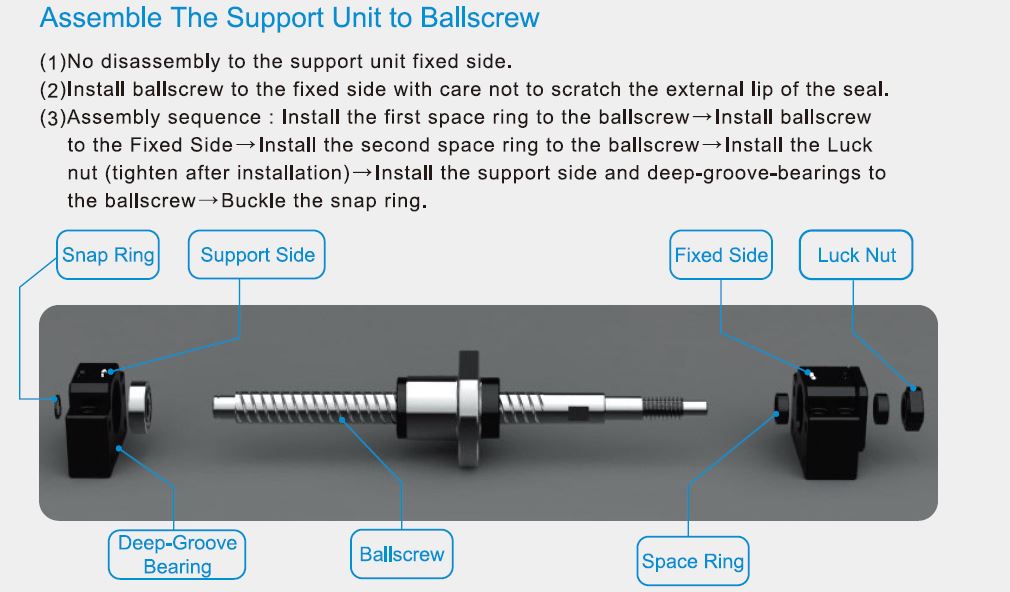

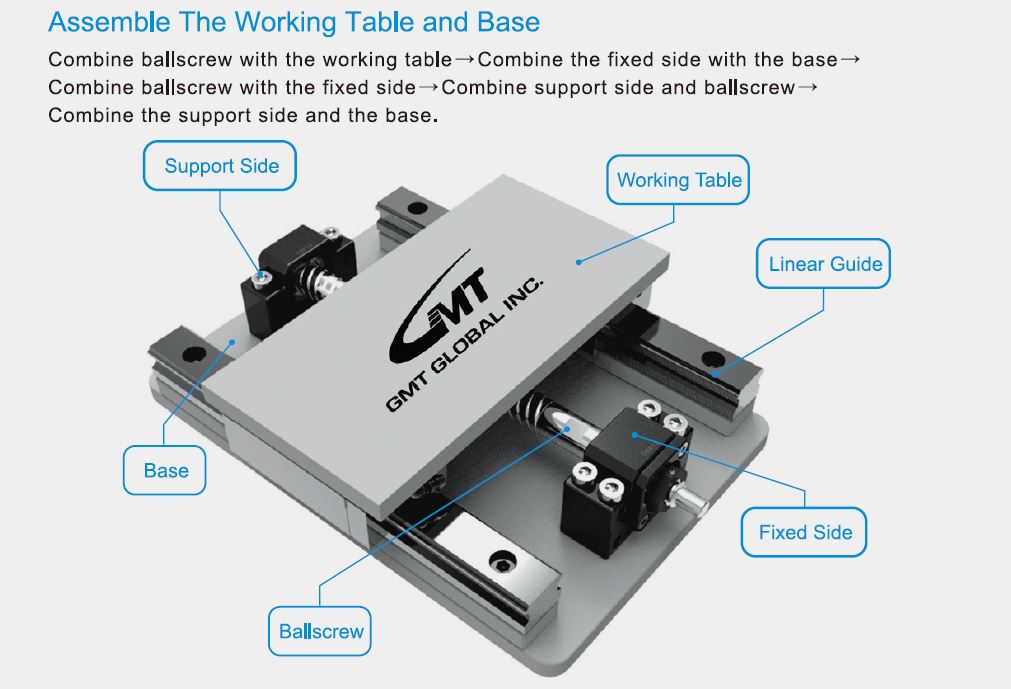

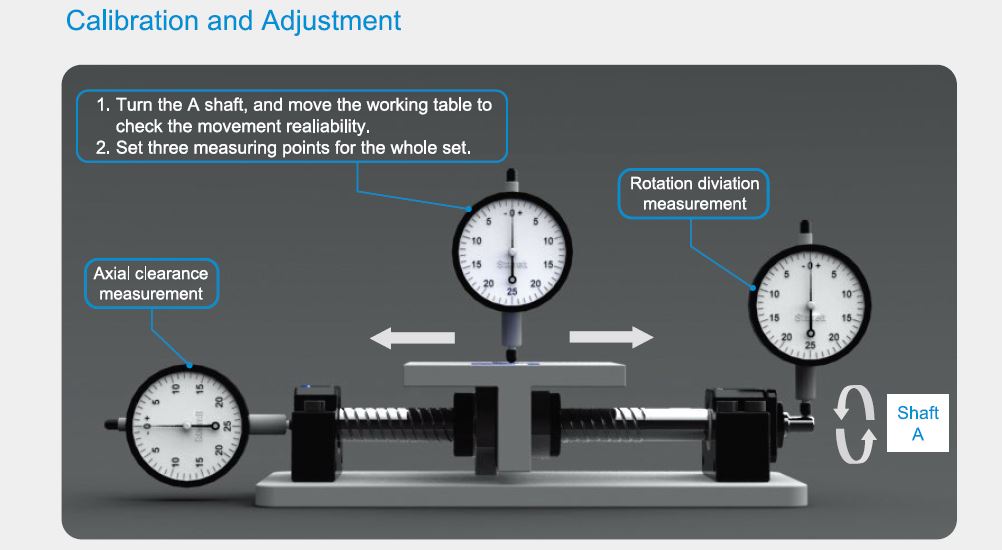

| Support Unit Assembly models & Steps |

|

Reviews

There are no reviews yet.