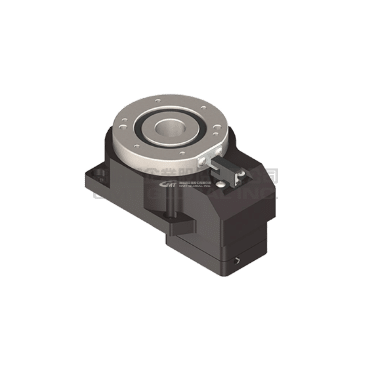

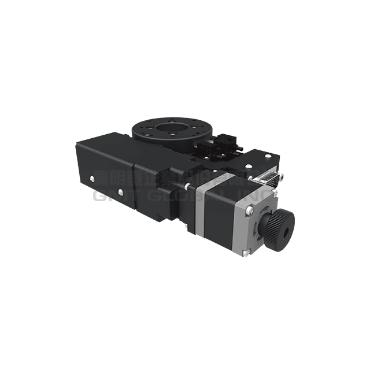

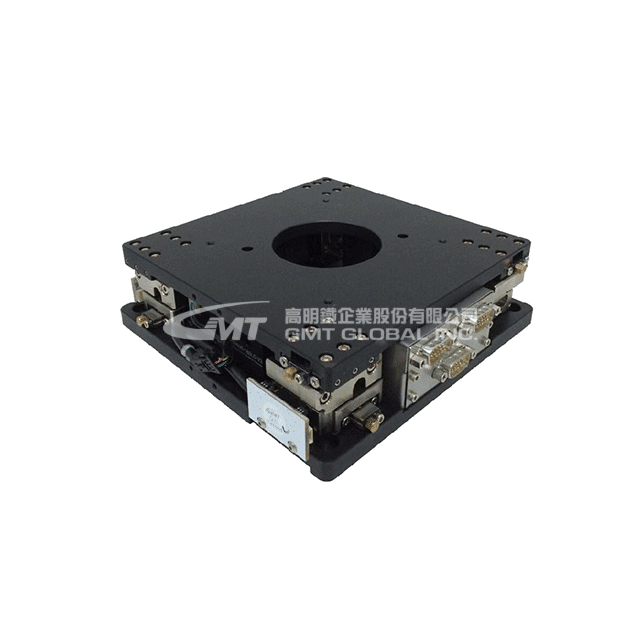

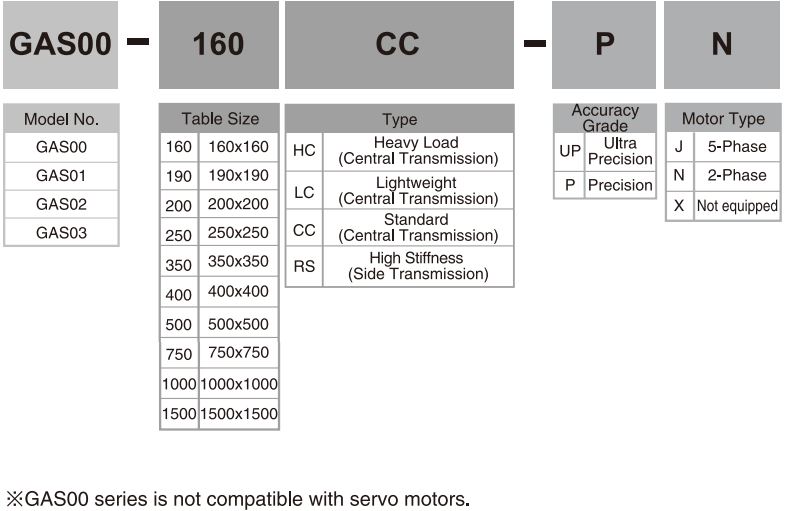

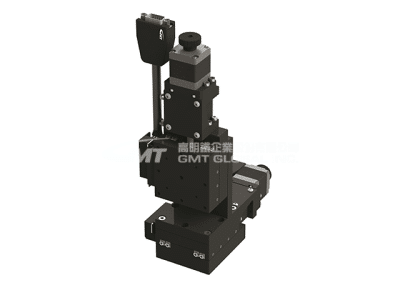

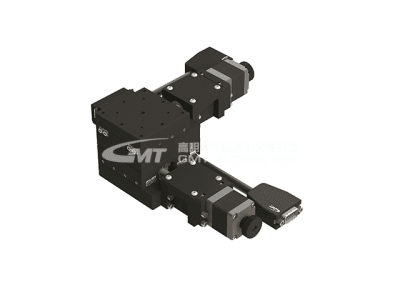

Alignment Stage-GAS00 Series

★ Light-weight and Extra-thin-It creates the wing-free thin & lighter mechanism by applying the XYθ module.

★ The cross-roller bearings have been pre-loaded, to perform the whole unit high precision and rigidity.

★ Hollow structure-It can be used for the optical inspection devices or conduction tester.

★ Longer usage life and reliable accuracy of the Alignment stage itself is guaranteed by lubrication.

★ All products are Cryogenic Treatment. It can not only significantly upgrade the toughness and operation lifetime but also improve the dimension stability of materials.

★ 3D CMM- Ensure the quality and precision of the stage.

|

odel No. |

GAS00-160LC-PN |

GAS00-160LC-UPJ |

GAS00-160EC-PN |

GAS00-160VC1-PN |

GAS00-160VC1-UPJ |

GAS00-190EC-PN |

GAS00-190EC-UPJ |

GAS00-190HC-PN |

GAS00-190HC-UPJ |

GAS00-200HC-PN |

GAS00-200HC-UPJ |

|

Stage Size (mm) |

160×160 | 160×160 | 160×160 | 160×160 | 160×160 | 190×190 | 190×190 | 190×190 | 190×190 | 200×200 | 200×200 |

|

Base Size (mm) |

170×170 | 170×170 | 170×170 | 170×170 | 170×170 | 210×210 | 210×210 | 210×210 | 210×210 | 210×210 | 210×210 |

|

Height (mm) |

50 | 50 | 50 | 55 | 55 | 65 | 65 | 65 | 65 | 60 | 60 |

|

Travel Stroke (mm) |

±3x±3 | ±3x±3 | ±3x±3 | ±9x±9 | ±9x±9 | ±4x±4 | ±4x±4 | ±4x±4 | ±4x±4 | ±7x±7 | ±7x±7 |

|

Angle (θ)° |

±2° | ±2° | ±2° | ±8.5° | ±8.5° | ±3° | ±3° | ±3° | ±3° | ±3° | ±3° |

|

Stage Material |

Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel | Carbon Steel |

|

Stage Surface Treatment |

Black Finished | Black Finished | Black Finished | Black Finished | Black Finished | Black Finished | Black Finished | Black Finished | Black Finished | Black Finished | Black Finished |

|

Base Material |

Duralumin | Duralumin | Duralumin | Carbon Steel | Carbon Steel | Duralumin | Duralumin | Duralumin | Duralumin | Duralumin | Duralumin |

|

Base Surface Treatment |

Black Anodized | Black Anodized | Black Anodized | Black Oxide | Black Oxide | Black Anodized | Black Anodized | Black Anodized | Black Anodized | Black Anodized | Black Anodized |

|

Ball Screw Spec. |

Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø6-P1 | Ø8-P1 | Ø8-P1 |

|

Dynamic Load Capacity (kgf) |

30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 60 | 60 |

|

Static Load Capacity (kgf) |

60 | 60 | 60 | 120 | 120 | 60 | 60 | 65 | 65 | 130 | 130 |

|

Repeatability Accuracy (μm) |

±5 | ±1 | ±5 | ±5 | ±1 | ±5 | ±1 | ±5 | ±1 | ±5 | ±1 |

|

Parallelism (μm) |

30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

|

Motor Brand |

GMT | Oriental | GMT | GMT | Oriental | GMT | Oriental | GMT | Oriental | GMT | Oriental |

|

Motor Type |

2-Phase Stepper | 5-Phase Stepper | 2-Phase Stepper | 2-Phase Stepper | 5-Phase Stepper | 2-Phase Stepper | 5-Phase Stepper | 2-Phase Stepper | 5-Phase Stepper | 2-Phase Stepper | 5-Phase Stepper |

|

Motor Shaft |

□28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □28 Double Shaft | □42 Double Shaft | □42 Double Shaft |

|

Motor Model. No. |

2MS-

N28D32 A |

PKP523

N12B |

2MS-

N28D32 A |

2MS-

N28D32 A |

PKP523

N12B |

2MS-

N28D32 A |

PKP523

N12B |

2MS-

N28D32 A |

PKP523

N12B |

2MS-

N42D47 A |

PKP544

N18B |

|

Driver Brand |

Contact us | Oriental | Contact us | Contact us | Oriental | Contact us | Oriental | Contact us | Oriental | Contact us | Oriental |

|

Driver Model. No. |

Contact us | CVD512

-K |

Contact us | Contact us | CVD512

-K |

Contact us | CVD512

-K |

Contact us | CVD512

-K |

Contact us | CVD518

-K |

| Characteristics |

| ♦ Ultra thin appearance

Achieved with the lighted crossed roller bearings and modularized structures. ♦ High stiffness and high precision Applying preload operations on every roller bearings of stages for better rigidity and precision. ♦ Hollow structure Lightweight structure of the stages could be suitable for optical inspection devices. ♦ Lubrication system Well lubricating gives the stages longer using life and reliable accuracy. ♦ Genericity Available sizes from 160mm to 1500mm, even capable of heightening load resistance by adding driven modules. |

| Applications |

| ♦ Panel lamination machinery

♦ Panel film laminating machines ♦ Print screen and 3D printing ♦ Angular glass cutting and grinding equipment ♦ Wafe alignment equipment ♦ P.C.D exposure equipment ♦ Software cutting equipment ♦ Semi-conductor equipment |

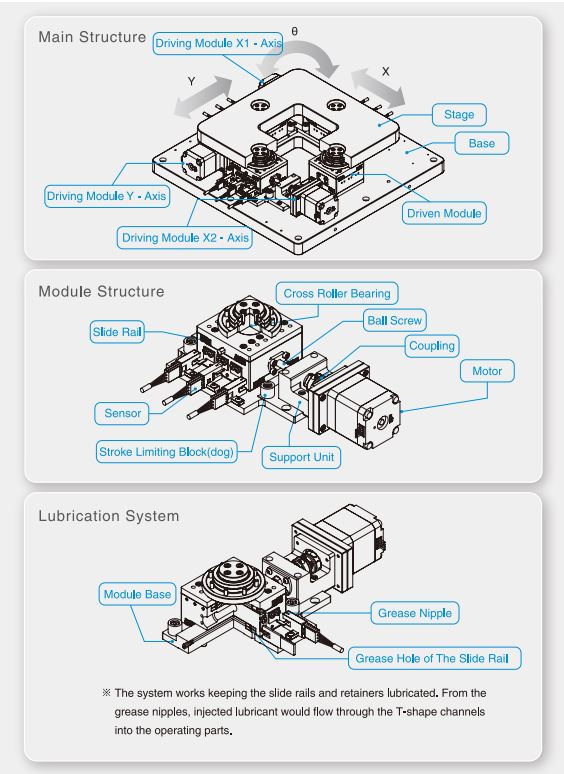

Structures and Lubrication System |

|

|

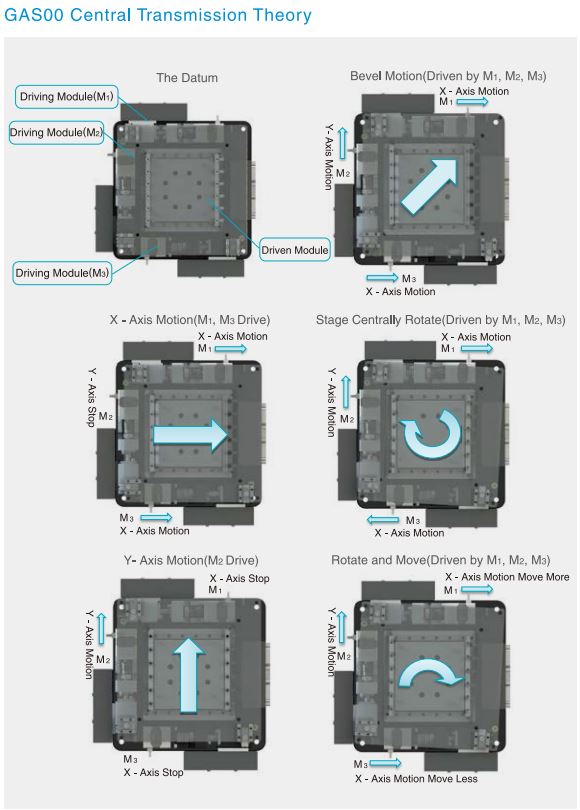

Transmission Theory |

|

|

Reviews

There are no reviews yet.