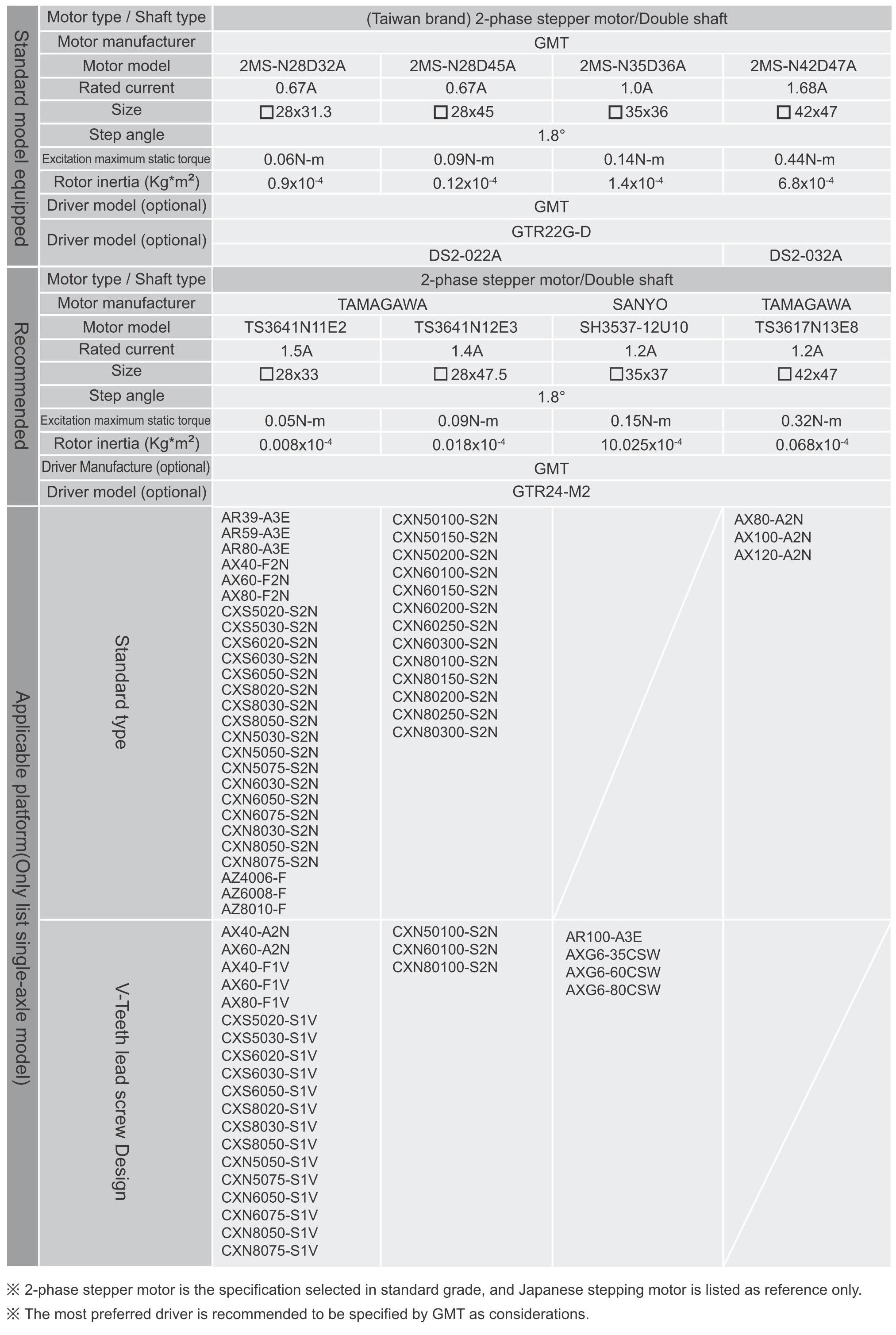

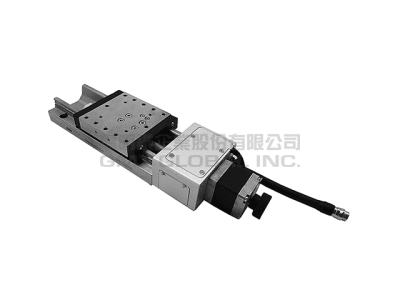

CXN50 – Ultra Precision

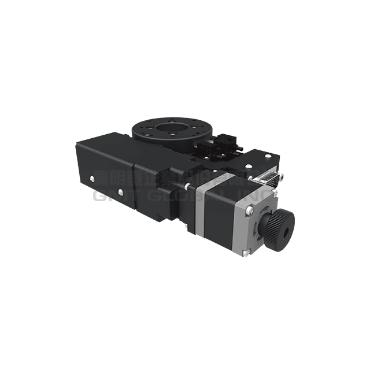

★ Guide- Circular linear ball guiding, Gothic arc-groove formed by dual arc-grooves individually on upper and lower rails of body. Ball moving in single groove is structured by 2 points-contact, and total 4contact points in dual arc-groove to form strong rail constructure.

★ Transmission Parts-Ball screw, It transmits through the ball involving in the locknut and screw to reach the accuracy and longer operation lifetime.

★ Material-Stainless Steel

|

Model No. |

CXN50 |

|||||

|

Mechanical Spec. |

Table Size (mm) |

50X50 | ||||

|

Travel Stroke (mm) |

30 | 50 | 75 | 100 | ||

|

Drive Type |

Ball Screw Ø8,lead 1mm | Ball Screw Ø8,lead 2mm | ||||

|

Rail |

Circular Linear Ball Guiding | |||||

|

Stage Material / Surface Treatment |

Stainless Steel / Nickel plating | |||||

|

Accuracy Level |

OP:Ultra Precision | |||||

|

Wiring Method |

N:GMT Standard | |||||

|

Precision Spec. |

Resolution(Pulse) (µm) |

M: 1 (Full);0.5 (Half)

J: 2 (Full);1 (Half) |

M: 2 (Full);1 (Half)

J: 4 (Full);2 (Half) |

|||

|

Max. Speed(Full Step) (mm/sec) |

15 | 30 | ||||

|

Positioning Precision (µm) |

5 | 7 | 10 | |||

|

Repeatability Precision(µm) |

±0.5 | |||||

|

Multi-point Repeatability Precision(µm) |

A: 1.5 / B: 1 | |||||

|

Load Capacity (Kgf) |

8 | |||||

|

Missed Step (µm) |

1 | |||||

|

Moment Stiffness |

Pitch: 0.08 / Yaw: 0.08 / Rolling: 0.08 (“/N-cm) | |||||

|

Pitch / Yaw |

Pitch: < 20″ / Yaw: < 15″ | |||||

|

Parallelism (µm) |

15 | |||||

|

Dynamic Straightness (µm) |

2 | 4 | ||||

|

Dynamic Parallelism (µm) |

10 | |||||

|

Electrical Spec. |

Motor |

Type / Shaft Numbers |

M: 5-phase stepper high-resolution motor / ☐28 double shafts

J: 5-phase stepper motor / ☐28 double shafts |

|||

|

Brand / Model |

M: Orientalmotor / PK523HPMB

J: Orientalmotor / PKP523N12B |

|||||

|

Driver Brand / Model |

Orientalmotor / CVD Series – 5 Phase stepping motor (Additional options) | |||||

|

Connector |

Stage Side Connector |

15-Pin male end connetor D-SUB / 12-Pin male end connetor HRS | ||||

|

Controller Side Connector |

15-Pin female end connetor D-SUB (Additional options) / 12-Pin female end connetor HRS (Additional options) | |||||

|

Sensor |

Origin Sensor |

Photoelectric sensor GMT-sensor | ||||

|

Limit Sensor |

||||||

|

Origin Approximation Sensor |

N / A | |||||

|

Power Voltage |

24V±10% | |||||

|

Control Output |

NPN open collector output under 24V 8mA | |||||

|

Output Control |

Testing (sensing):output transistor OFF (closed) | |||||

| Multi-point repeated positioning accuracy |

| ♦ Accuracy measurement description

1. Unidirectional positioning accuracy: within the range of the predetermined detection stroke, starting from a starting position, moving and positioning in a certain direction sequentially, and detecting the actual ♦ Precision introduction 1. Design the GMT high-level precision inspection method to meet the precision requirements of fiber coupling and semiconductor manufacturing process. |

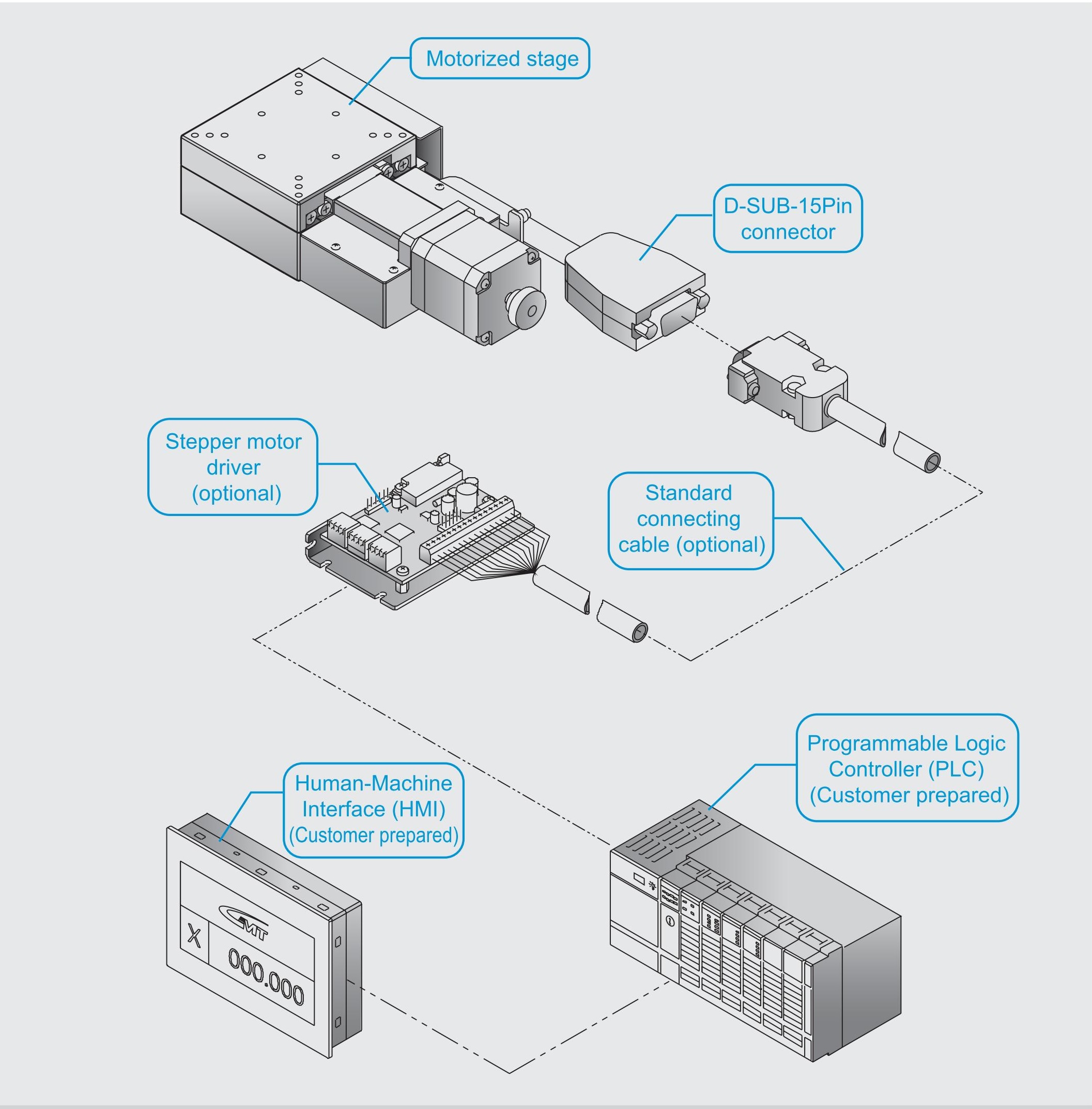

| System Configuration Diagram |

| ♦ For detailed specifications, please read the description for the stage and connecting cable.

♦ For selection of driver, please refer to the cross-reference table for the motor/driver of the standard motorized stage or the GMT motor and driver catalog. ♦ The most preferred driver is recommended to be specified by GMT as considerations. For different needs, please choose the suitable driver based on real functional needs. |

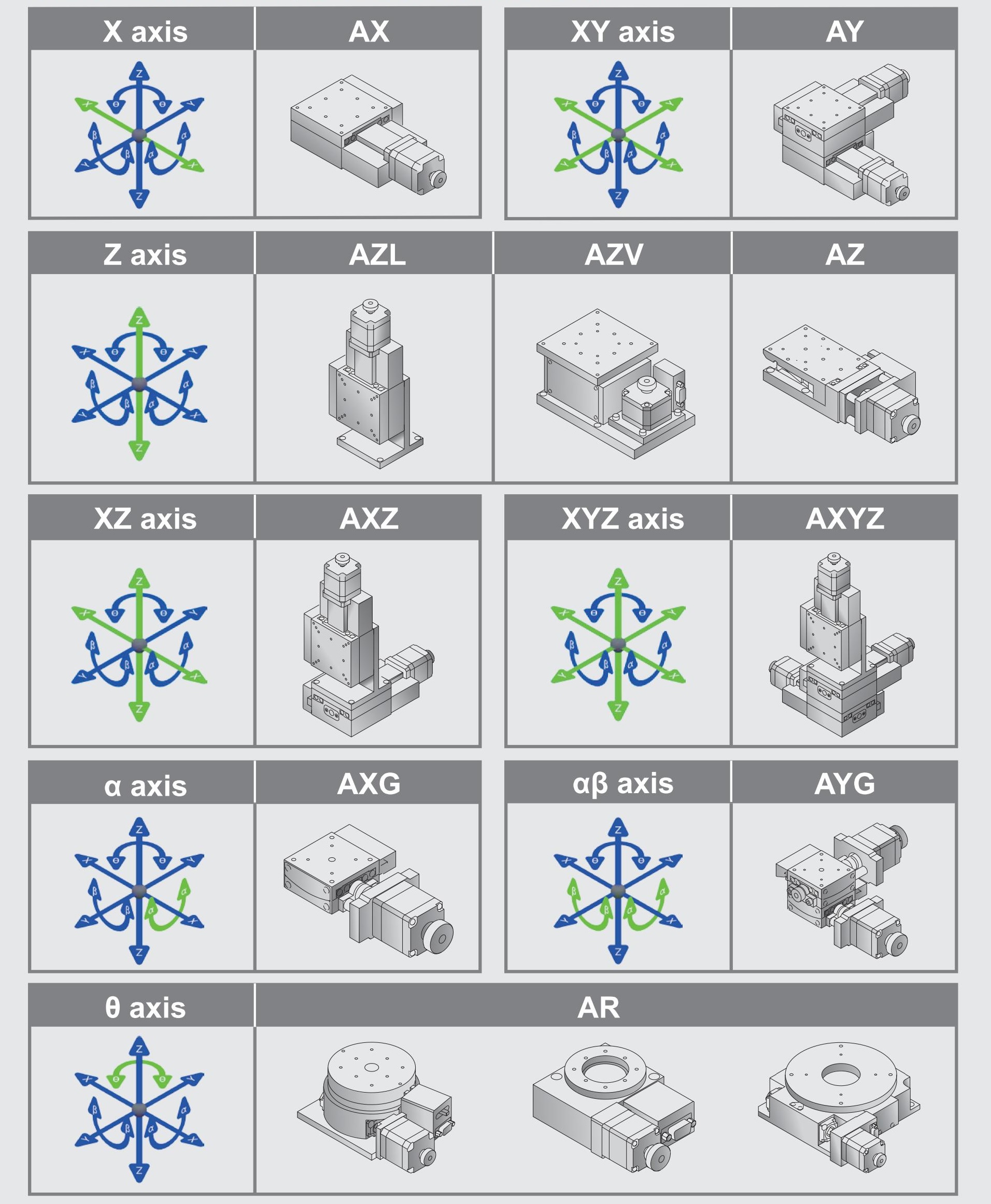

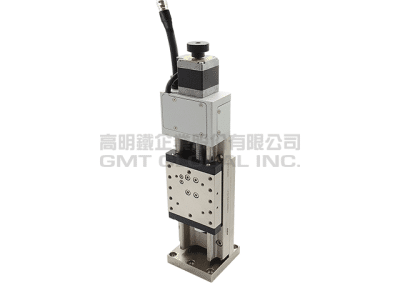

| Axis Definition |

| GMT has defined different axis as the following figuration according to the movement direction:

Horizontal movement direction is X and Y axis. Vertical movement direction is Z axis. Movement around X, Y, Z axis is defined to α axis, β axis, and θ axis. Green arrows present the specified axis movement direction. |

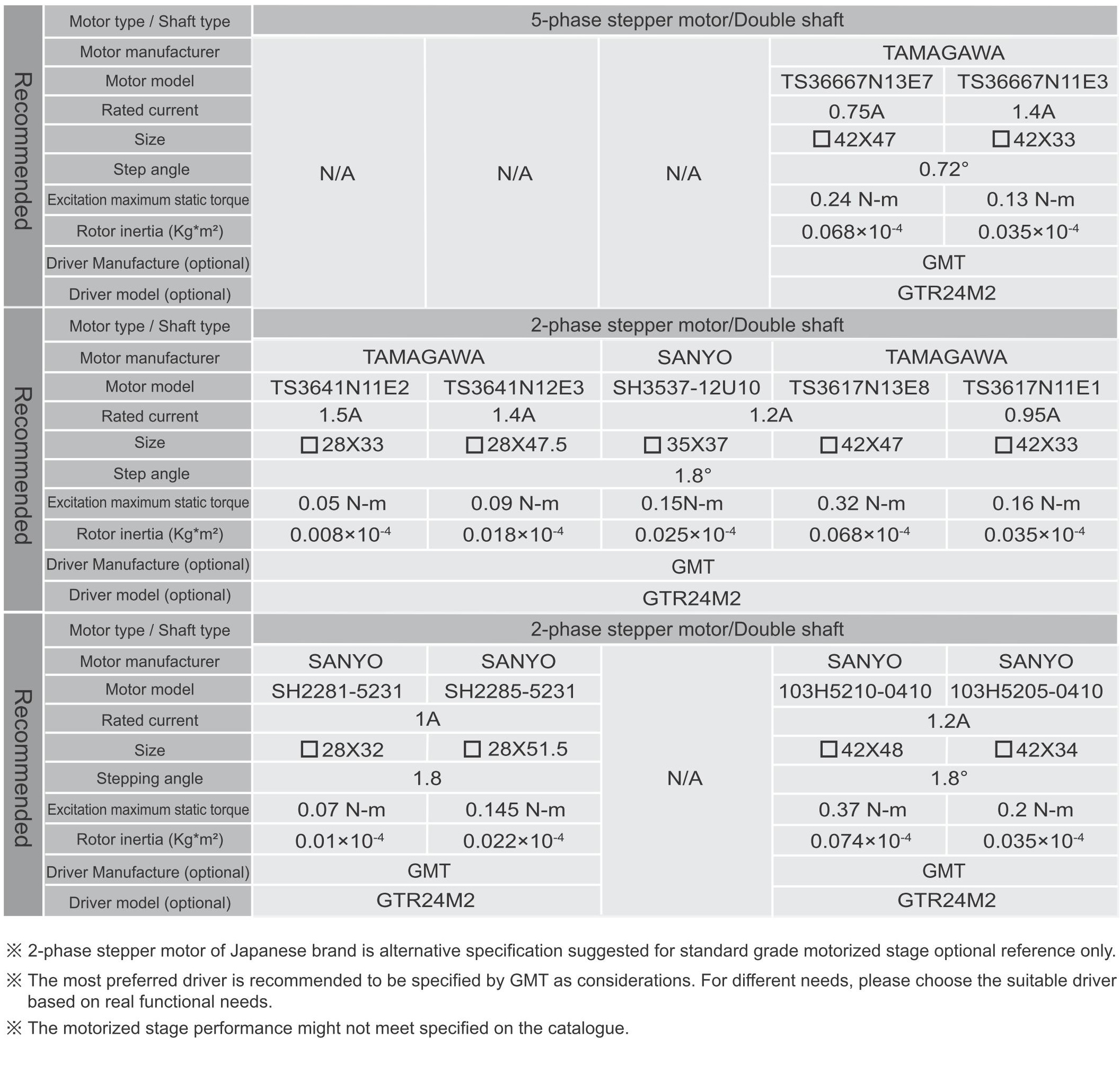

Motor/driver |

|

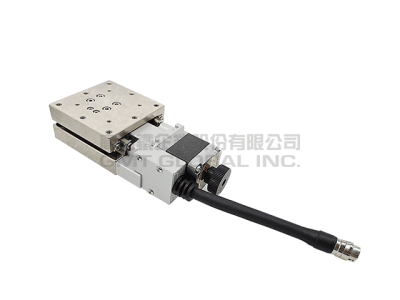

Ball Screw Ø8,lead 1mm

.jpg)

Reviews

There are no reviews yet.